Unlocking scheel-mann Seat Upgrade for the 2nd Gen Toyota Sequoia

- Services @ TS

- Dec 13, 2025

- 5 min read

Updated: Dec 21, 2025

A Technical Case Study in Platform Validation and System Integration

Toyota platforms evolve incrementally. Most solutions are best approached as variants of an existing architecture, not as entirely new systems.

That was the case with the 2nd Gen Toyota Sequoia.

This case study documents how a complete scheel-mann driver-side seat upgrade was validated on a specific vehicle, covering mount fitment, safety electronics, and factory seat heater integration. The outcome is a standardized, repeatable solution that can now be offered as a complete seat, mount, and harness package for applicable configurations, with no warning lights and full retention of factory features.

Treating the Sequoia as a Platform Variant

From the outset, the 2nd Gen Sequoia was evaluated as a close relative of the Tundra and 5th Gen 4Runner platforms. The underlying safety architecture, seat electronics, and control strategies are fundamentally shared.

The objective was not to invent a new approach, but to confirm whether existing assumptions held true on the Sequoia and to identify any platform-specific differences that required accommodation.

That approach proved correct.

The final solution aligns closely with established 5th Gen 4Runner architecture, with one notable platform evolution related to seat belt sensing that had not previously been encountered.

Verifying Physical Compatibility First

Before any electrical work began, physical compatibility had to be confirmed.

Based on known platform similarities, it was expected that the Tundra mounting architecture would translate directly to the 2nd Gen Sequoia. Confirmation matters, however, when seat geometry, belt anchoring, and airbag alignment are involved.

Validation was therefore performed in stages.

The mounting system was installed and test-fit in the vehicle before any additional components were released. Fitment was confirmed with no interference, no alignment issues, and no required changes. Floor attachment points, clearances, and seating position all aligned as expected.

Once mount compatibility was confirmed, the remaining components were released sequentially:

Only after the mechanical system was fully validated did electrical integration begin.

Customer Participation During Validation

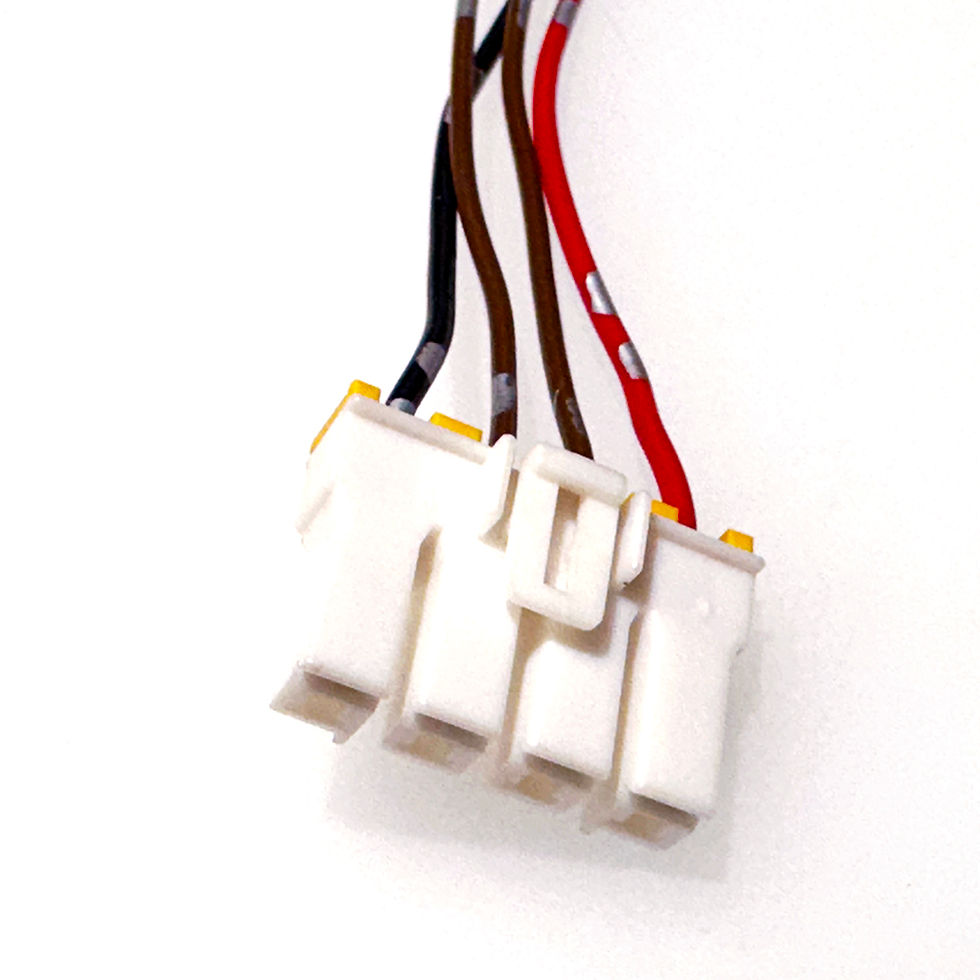

An unanticipated factor in this project was the level of engagement from the vehicle owner during validation. The under seat harness was removed from the Sequoia and shipped to us.

The customer was responsive, detail-oriented, and consistently willing to provide clear photos and feedback as questions arose. That participation accelerated validation on a platform that had not yet been formally confirmed. Going forward, Sequoia owners won't need to go to this extent. The hard work is done.

While the circumstances that enabled this validation were specific to this vehicle, the outcome is a standardized product offering, not an ongoing custom or case-by-case process.

Seat Belt System: Preserved as Designed

No modifications were made to the factory seat belt buckle or its associated wiring.

The original Toyota seat belt buckle and harness were transferred to the new seat and plugged directly back into the factory floor connector. No splicing, alteration, or electrical substitution was required.

During this process, it was observed that Toyota now uses a magnetic (hall-effect) switch inside the seat belt buckle assembly rather than a traditional mechanical switch. This represents a platform-level design evolution rather than a documentation omission.

Earlier platform notes did not include this detail because prior Toyota platforms did not implement this sensing method. Once identified, it was fully accounted for by preserving the factory buckle system intact.

Seat belt status reporting functioned normally once reinstalled.

Seat Position Proximity Sensor Behavior

Like other late-model Toyota platforms, the 2nd Gen Sequoia uses a seat position proximity sensor as part of its airbag logic. This hall-effect sensor determines whether the driver seat has entered the final portion of its forward travel toward the steering wheel.

The sensor’s function is binary. It does not measure occupant size or continuous seat position. Its sole purpose is to indicate whether the seat is fully forward, which informs airbag deployment behavior.

Sensor Placement on the Aftermarket Mount

The proximity sensor does not have a dedicated mounting location on the aftermarket seat mount. Because it is a hall-effect device, it only requires a stable magnetic reference.

In this case, the sensor was secured magnet-side against the steel seat mount using a non-permanent retention method, with sufficient slack to allow full seat travel. The seat was cycled through its entire range of motion to verify stable sensor behavior and proper harness routing.

The driver in this case study is 6’7” tall and operates the vehicle with the seat positioned well rearward of the full-forward travel limit, eliminating the possibility of unintentionally triggering the proximity threshold.

This handling is documented here strictly as part of this case study.

Seat Heater Integration

With mechanical fitment and safety systems validated, the remaining task was seat heat integration.

The 2nd Gen Sequoia uses a factory seat heater control module governed by dash switch inputs and temperature feedback. This architecture mirrors the 5th Gen 4Runner.

The limiting factor is hardware availability. The 4-pin connector that plugs directly into the Toyota seat heater control module is not available through Toyota or any aftermarket supplier.

As a result, a short section of the original factory seat heater harness containing that connector must be reused. This is the same connector and reuse strategy employed on 5th Gen 4Runner heater harnesses, where a core charge is applied to account for the recovered OEM component.

No vehicle-side wiring is modified.

System-Level Heater Architecture

The embedded schematic illustrates the final system-level integration.

The factory heater control module remains fully in control. Purpose-built harnesses bridge the OEM system to the scheel-mann heating elements, which operate as downstream loads under Toyota’s original logic.

Important notes

Applies to 2nd Gen Sequoia with factory power and heated driver seat

Driver seat only at this time

Configuration validated on a 2017 model year

Reuse of OEM 4-pin heater module connector required

Other years may require verification

Final Harness Design and Validation

From the vehicle’s perspective, the final solution is plug-and-play. All safety-critical circuits are preserved, and the factory heater system remains intact.

Vehicle validation confirmed:

No SRS or airbag warning lights

No seat belt or seat position faults

Normal operation of factory seat heater switches

This configuration has been validated on a 2017 2nd Gen Toyota Sequoia equipped with factory power and heated driver seats.

Scope and Next Steps

The Sequoia solution closely follows established Toyota platform architecture and is best understood as a validated variant rather than a unique system.

Additional model years and passenger-side support will require separate verification before being formally released.

What This Unlocks

With mount fitment, safety electronics, and seat heater integration confirmed, a complete scheel-mann driver-side seat upgrade is now achievable for the 2nd Gen Sequoia.

What enabled this outcome was a methodical validation process applied to a new platform variant, resulting in a standardized product offering that preserves Toyota’s original safety and comfort systems without compromise. #ToyotaSequoia #2ndGenSequoia #ToyotaOverland #ToyotaBuild #OverlandToyota #Scheelmann #ScheelmannSeat #AftermarketSeats #ToyotaEngineering #SeatUpgrade #OverlandRig #ToleranceStack

Comments